Defining the Mortise and Tenon, Old and New

Defining the Mortise and Tenon, Old and New

The mortise and tenon joint is one of the oldest methods of joining two pieces of material together and certainly is still very much a mainstay in fine cabinetry work today. There are many references to mortise and tenon joinery throughout the ages. Historical monuments such as Stonehenge, the hulls of early boat and ship vessels, and even Egyptian sarcophagi were made with this frame construction. Whether stone, metal, or wood, the construction method is still very much the same.

The mortise is essentially a slot or a hole cut into or through one piece of material. The tenon is an extension milled onto another piece of material that will be fitted into the mortise. The outer dimension of the tenon matches in both shape and size to the inside dimension of the mortise. When the tenon is inserted into the mortise, the two pieces of material are joined.

In traditional woodworking, door and shutter frame mortises are milled into the vertical inside of each upright frame member. This upright frame member is called a stile. Mortises are placed where horizontal cross rails intersect. Cross rails, or simply rails, are the horizontal frame members. Rails are made over sized in length allowing for the ends to be milled down creating a tenon.

A well made deep fitted mortise and tenon is very strong since there is quite a bit of surface area contact between both pieces of wood. A snug fitting joint is the best as it will help to prevent the frame from racking. With the use of pegs, wedges or both wedges and pegs, as shown in the pictures of the shutters below, the parts are held tightly together creating a fastened joint.

These aged shutters are well over 100 years old. They are great examples to show mortise and tenon construction with the use of both peg and wedge fastening methods.

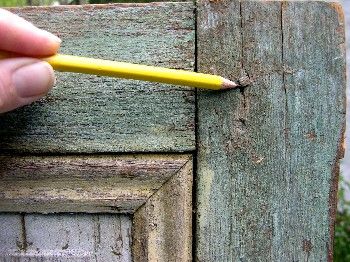

The shutter frames are fastened together with both pegs and wedges. The wedge is inserted in the opposite side of where the tenon was inserted. The peg is just below my thumb.

I pulled this wedge out for you to see. It is pretty amazing that someone a long time ago cut this and at least 11 more, all fitted perfectly by hand, for each pair of these exterior window shutters.

The mortise shown on these old shutters is called a through-mortise simply because it is open on both sides, milled all the way through the stile. This mortise and tenon was made to fit a wedge. The wedge pinches the tenon into the mortise slot and holds the joint together much like a wedge shape door stop holds a door open or shut.

Through mortises are seen on objects made in periods in time when milling machinery was not available or advanced enough in order to mill the material quickly and easily.

With the advent of machinery, through mortises for the most part were replaced with “pocket” mortises. Pocket mortises are just how the name sounds. The pocket mortise is open on one face only for the tenon to be received.

We have seen wedges used on many old shutters that we reproduced. However, since we use the pocket mortise and tenon method we only need to use pegs. Pocket mortises are very good for outside applications since end grain is not exposed. The reason that end grain should not be exposed is because just like a drinking straw will suck up water so does end grain. End grain is essentially very much like many tiny straws bundled together that supply the tree and it’s canopy with water. When end grain is exposed and proper maintenance is not provided it will eventually lead to deterioration.

More then likely these old shutters would still be hanging if they had had just a little more maintenance with finishing as it appears that this paint is the original finish. For being as old as these shutters are they are still held together rather well because of the well made mortise and tenon construction.

Pegs are inserted into a hole that has been drilled through the face of the shutter through the mortise and tenon joint. The peg acts much like a cotter pin locking the two pieces together.

The mortise and tenon joint is a very old construction method and still one of the best woodworking types of joinery today. Our interior shutters, exterior shutters as well as all of our doors are assembled using this method of joinery.

When we assemble door and shutter frames a light application of glue is applied to the mortise and tenon joint areas. Then the parts of the frame are fitted together along with the components that will be inside of the frame such as operable or fixed louvers or even solid wood panels. The shutter or door is then clamped together to tighten and flush all of the joints. When the joints are flush and tight a hole is drilled through the mortise and tenon for the pegs. After the pegs are inserted the joint is now locked together and the clamps are released. At this point this joint can take extreme force and still not pull apart and it will undoubtedly last as long as the old shutters shown in this post, if not longer.

Did you know? Just because a wood product can mention made with “mortise and tenon construction” does not imply that it is good unless it is properly made. When mortise and tenon joints are too loose, improperly fitted, the joint will fail and the frame will rack.

Post written by Jewel Foulds, April 2008

Spring is no doubt one of my favorite things. Nature is fresh and full of color. I was lucky to capture this picture just recently. This spring time beauty known as ‘Bleeding Heart’ is an Old Fashioned favorite in many gardens.

Kestrel Shutters & Doors, Inc. www.DIYShutters.com

Celebrating our 19th Year in business on May 4, 2008

Very informative posts, glad I found this site. Thanks!